Bonding rebond

It is often necessary to re-bond a bare die. Typical reasons include:

- Original bond wires were accidentally destroyed during decap

- Device was obtained as a bare die from a third party

- FIB edit could not be done with device in package due to mechanical constraints

Several firms sell refurbished wire bonders and provide service, support, and parts. Some of these companies will also do custom bonding projects for single dies or small lots.

Contents

Surface preparation

If any existing bonds, or pieces of them, are still on the pads these must be removed first.

Pads should be clean and relatively undamaged. A small amount of cratering from a previous bond is OK as long as there is still sufficient metal underneath to make a solid connection.

Mounting

The die must be secured firmly to its new package to keep it from moving around. AZ has had good experiences using a tiny dot of cyanoacrylate adhesive, although silver epoxy or Crystalbond would likely work fine as well. Make sure the volume of adhesive is low enough that it doesn't squeeze out and get on the top of the die.

Re-bonding

Bonding to a clean, once-bonded pad should be essentially the same as bonding to a never-bonded pad. Contact resistance may be a little higher and reliability reduced, but this isn't a big concern if you just want to dump the firmware.

Bondable materials

Bondable surfaces are generally soft metals with minimal oxidation (thin native oxide will be penetrated by the "scrubbing" action of the ultrasound, but thicker oxides will cause problems)

- Aluminum bond pads

Good results as long as bond wires were removed cleanly - Copper bond pads

AZ has no experience with these - Bare copper PCB surface* AZ had issues due to oxidation on a board that had been sitting around for a while. After sanding the surface with 450 grit paper it was too rough for bonds to stick. Further research needed. Copper SEM mounting tape didn't seem to work either.

- Gold plated CERDIP pads*

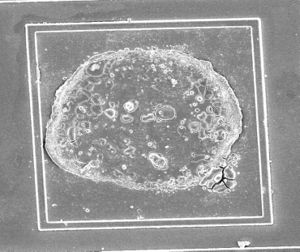

Good results - ENIG PCB finish* This is not normally considered a bondable material (50-125 nm of Au, typical "bondable gold" plating is 750-1250 nm) so results may vary, but in AZ's experience acceptable performance for RE purposes can usually be obtained. Photo below is of bonds between adjacent pads on a 1.27mm pitch SOIC breakout board.

- Pb HASL* Not bondable under any process parameters tested. First bond sometimes sticks but second lifts up during tear-off.

- FIXME: Try bonding to FIB deposited Pt

- FIXME: Try bonding to FIB deposited W

Tool-specific notes

Commercial companies / other resources

http://www.forcetechnologies.co.uk/services/manufacturing/die-reclamation

- Mechanically removes bond wires

- Wick solder bumps to gold surface