Difference between revisions of "Allied MultiPrep"

(Tag: Visual edit) |

(Tag: Visual edit) |

||

| Line 69: | Line 69: | ||

<br /> | <br /> | ||

==Head connector== | ==Head connector== | ||

| + | |||

| + | Official cable uses 24 AWG (Carol C0603) | ||

Revision as of 04:07, 8 June 2020

Contents

Motor

Both motors (drive, osc) are identical

Healthy readings TLDR

- 6 ohm nominal

- Higher indicates carbon dust, possibly much higher (eddy currents I guess)

- Vmax

- Motor: 19.1 V

- Osc: 7.6 V

- Drive: 15.0 V

- No load test

- Healthy around

- 12.21 V @ 153 mA

- 12.21 V @ 180 mA

- Old motors: 12.22V @ 1.25 A

- Healthy around

PITTMAN GM8712-41 19.1 VDC 187:1 RATIO MFG 05-29-98 S

33 and 17 ohm. Is one of these damaged? Why are their resistances so different?

Tried testing under load

- black goop

- 12.19 V @ 1.266 A (current limited)

- 8 ohm after

- other

- Initially drawing way less current than first

- 12.12 V @ 0.332 A (voltage limited)

- then started smoking

- 11.68 V @ 1.248 A (current limited)

- 6 ohm after

- Initially drawing way less current than first

Aren't these rated 19.1 V? Am I misunderstanding?

Try pinning out the spare bad head

- 1-5: 2.8 k

- 2-6: 147 R

- weird...

what does the secondary machine test? (believe good)

- 1-5: 9.0 R

- 2-6: 10.4 R

What is max voltage allied puts out on motors?

- 4-8

- 7.6 (fixed)

- osc

- 3-7

- 15.0 (max)

- drive

Head connector

Official cable uses 24 AWG (Carol C0603)

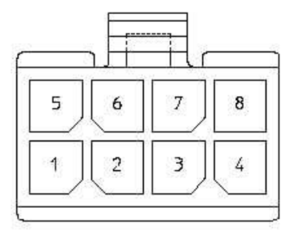

Head plug

- 4x2 (8 pins)

- 3 mm pitch

- Head female, cable male

- Molex Microfit 3

- aka Amphenol Minitek Pwr™ 3.0 Series

- https://www.digikey.com/product-detail/en/amphenol-icc-fci/10132445-08LF/609-5283-ND/7590945

- aka Amphenol Minitek Pwr™ 3.0 Series

| Microfit 4x2 | Signal | Breakout cable color | Notes |

|---|---|---|---|

| 1 | Hall | Black | |

| 2 | Hall w/ cap | Red | |

| 3 | Drive | Orange | |

| 4 | Osc | Yellow | |

| 5 | Chassis ground | Green | N/C on main cable |

| 6 | Hall w/ cap | Blue | |

| 7 | Drive | Violet | |

| 8 | Osc | White |

| Microfit old | Microfit

correct |

mini-DIN | Signal | Note |

|---|---|---|---|---|

| 1 | 4 | 1 | ||

| 2 | 3 | 2 | ||

| 3 | 2 | 8 | ||

| 4 | 1 | 7 | ||

| 5 | 8 | 3 | ||

| 6 | 7 | 5 | ||

| 7 | 6 | 6 | ||

| 8 | 5 | N/C |

| Microfit | mini-DIN | Signal | Note |

|---|---|---|---|

| 1 | |||

| 2 | |||

| 3 | |||

| 4 | |||

| 5 | |||

| 6 | |||

| 7 | |||

| 8 |

Motor on mini-DIN

- 1: drive motor +

- 3: drive motor -

- 7 V

| Microfit old | Microfit

correct |

cpc | Signal | Note |

|---|---|---|---|---|

| 1 | 4 | 8 | ||

| 2 | 3 | 6 | ||

| 3 | 2 | 1 | ||

| 4 | 1 | 4 | ||

| 5 | 8 | 5 | ||

| 6 | 7 | 3 | ||

| 7 | 6 | 2 | ||

| 8 | 5 | N/C |

Tach board

- Adapts 8 pin to 4 pin

- Includes cap + 4 pin SMD component (489, probably hall effect sensor)

- Must interface to those two red things I was confused about...looks like they have magnets on the end

- Minitek 4x2

- 4: 4x1.1

- 3: 4x1.3

- 2: hall, cap

- 1: hall

- 8: 4x1.2

- 7: 4x1.4

- 6: hall, cap

- 5: chassis ground

- 4x1

- 1: osc

- 2: osc

- 3: drive

- 4: drive

Test primary machine motor via 4x1

- drive: 10.2 R

- osc: 5.6 R

- *** out of spec

- consistent with a failed motor

failed motors appear to be caused by carbon buildup from brushes. They will fail very quickly if you operate them even close to their rated voltage. I was able to disassemble and blow one out to fix it. Now it runs at about 12.22V @ 350 mA. Current went down over time, maybe was 500 mA initially

Lets try another... initially 12.22V @ 1.25 A. Visible smoke. Rotor very dirty...should have cleaned other rotor. After cleaning dropped to 12.22V @ 1.1A and then rose up. Hmmm. Clean between rotar contacts. Success! Now 12.21 V @ 153 mA! Significant improvement! 9.6 ohm now

Back to original motor. Cleaned, now drawing 12.21 V @ 0.180 mA. Seems pretty concrete: needs to be cleaned, especially between rotar contacts. Try 18.86 V @ 197 mA. 9.6 ohm

Try osc motor. Didn't try running initially for fear of damaging. After cleaning (worst of all motors so far) 12.19V @ 175 mA. Current seems to be going down as well. 12.19 V @ 200 mA installed. However system is still not turning it (ie its not applying voltage). Other motor is about the same (even though it wasn't cleaned).

Osc 9V on 8 pin. Osc motor being driven at 1.3V. Maybe power supply is failing? Motor current via benchtop PS seems okay to me. Cross strapped channels and verified drive channel can drive either drive or osc, but osc cannot drive either channel. Probably need to open the unit up

McMaster misc

2020-01-14

- Win cross sectioning kit

2020-02-20

- Order sample holder

- Order replacement tubing

- Later found I had some spare, but meh can use for other projects

2020-05-06

- Measure grommets

- 23 mm diameter

- 11.5 mm high (0.45")

- 6.5 mm center

- Measure hole

- 25.3 mm diameter

- Grommet must be less than this

- ~9.15 mm high (0.36")

- Grommet must be higher than this

- 25.3 mm diameter

- Bolts

- 1/4-28 IIRC

- Around 6.25 mm OD

- Options

- https://www.mcmaster.com/90131a102

- Abrasion-Resistant Cushioning Washer

- for 1/4" Screw Size, 0.25" ID, 0.75" OD

- 0.110"-0.140" high

- Need: 12

- https://www.mcmaster.com/9540K914

- Heavy Duty, SBR Rubber, 15/16" OD, 1/2" High

- 3/8" ID

- Ned: 3

- https://www.mcmaster.com/90131a102

McMaster newer

S/N 568

Hermitage: Allvia Sunnyvale? Not sure if they are still in business

2019-12-19

- Submitted offer. Negotiations failed

2020-02-19

- Seller accepted offer (was firm at old offer). Local pick up

2020-02-232

- Swap DRO from spare to primary machine

- Replace rusted micrometer

2020-02-23

- Observe osc motor is not moving

- Observe osc doesn't have slit like spare to keep in place...how is it supposed to work?

- Is this a DRM thing of sort where they didn't supply the right adapter if the user didn't purchase osc option?

- ie the motor was intentionally disabled and also mechanically hindered

McMaster older

???

- Won a few lots of parts TechPrep heads

- Goal: combine into one good head and mount on SBT machine

2019-03-20

- Try to get old TechPrep base. Negotiations failed

2019-12-20

- Won old TechPrep base machine. Change plan from retrofitting SBT machine to actually fitting on this machine

- Without reference machine a little difficult to piece together

- Machine filthy. Significant cleaning

2020-02-23

- Used reference machine to greatly accelerate repairs

- Made cable to hook up head

- E1.43 (error code?) persists, but machine seems to work fine

McMaster 2020-06-07

Test1: spare arm

Testing out arm on the table. I believe it was mounted on the newer machine

Goals:

- Understand osc motor

- Check motor health

- Clean arm. Some precision surfaces are dirty

Motor current tests

- Osc

- yellow +, white -

- 7.6 V @ 175 mA

- went down to 160 mA after a bit

- Motor not loaded (coupler removed from top)

- Spinning CCW

- Drive 15.0 V

- orange+, violet -

- Motor not loaded (removed rubber ring)

- 7.6V @ 150 mA

Conclusions:

- Pinout table is correct

- Motors work and are in spec

Test2: production arm

Osc

- 7.6V 2 180 mA under load

- Shows: motor is fine, I probably don't have the cable correct

Drive

- 7.6V @ 160 mA no load

- 170 mA w/ rubber attached

Conclusion: found loose wire.Take this as an opportunity to make a proper cable...either a new one or solder the existing one