Difference between revisions of "Chassis"

(Tag: Visual edit) |

(Tag: Visual edit) |

||

| Line 1: | Line 1: | ||

Information on microscope heavy duty chassis suitable for making custom microscope assemblies. The main issue is that most metallurgical microscopes have the XY stage integrated into a Z focus assembly that can't take a lot of weight and has little Z clearance. As motors and other accessories are added it may run out of clearance or be too heavy to operate correctly. | Information on microscope heavy duty chassis suitable for making custom microscope assemblies. The main issue is that most metallurgical microscopes have the XY stage integrated into a Z focus assembly that can't take a lot of weight and has little Z clearance. As motors and other accessories are added it may run out of clearance or be too heavy to operate correctly. | ||

| − | In lieu of this its generally better to get a microscope where the Z axis moves the optics instead of the stage. Some example microscopes using a heavy duty chassis like this: | + | In lieu of this its generally better to get a microscope where the Z axis moves the optics instead of the stage. Often these are sold as a "toolmaker microscope." Some example microscopes using a heavy duty chassis like this: |

*Olympus BHMJ | *Olympus BHMJ | ||

Revision as of 07:00, 18 August 2020

Information on microscope heavy duty chassis suitable for making custom microscope assemblies. The main issue is that most metallurgical microscopes have the XY stage integrated into a Z focus assembly that can't take a lot of weight and has little Z clearance. As motors and other accessories are added it may run out of clearance or be too heavy to operate correctly.

In lieu of this its generally better to get a microscope where the Z axis moves the optics instead of the stage. Often these are sold as a "toolmaker microscope." Some example microscopes using a heavy duty chassis like this:

- Olympus BHMJ

- Minnetonka Precision

- Mitutoyo toolmaker

- McBain Z-Scope

- Nikon toolmaker

The least expensive / most common is probably to get an Olympus BHMJ mount. These can be mounted on hardware store steel pipe to quickly and inexpensively make custom frames. The main disadvantage is it won't be as stable as other options (TODO: add picture of IR microscope).

Another option is to take a commodity metallurgical microscope and remove the original Z axis + XY stage entirely and add a new Z axis attached to the base. A good example of this type of setup can be found here: http://www.seanriddle.com/micro.html

BH2 Toolmaker

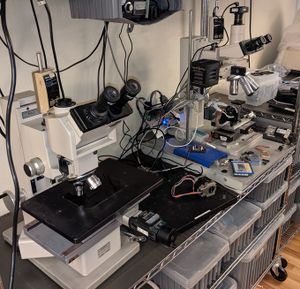

Above: McMaster 2 left, McMaster 1 right. 1 originally looked more like 2 but the bottom illuminator and original XY stage were removed

I've never been able to positively identify who makes it. The common parts are:

- Focus: crank for coarse focus as well as medium-fine focus knobs like on traditional microscopes

- Bottom illuminator

- Mitutoyo digimatic for Z measurement

Comparison as received:

| Component | Mc1 | Mc2 |

|---|---|---|

| XY stage | Style 1

Large Mitutoyo manual |

Style 2

Large Mitutoyo manual |

| Observation tube | Trinocular standard | Trinocular ergonomic |

| Objectives | Mitutoyo M Plan Apo | Olympus NeoDPlan, MSPlan |

| Illuminator | BH2-UMA

LH-50 lamphouse |

BH2-UMA (broken)

Fiber |

Focus: there is a slip plate that will very slowly drift over time. If you are doing sensitive measurements that need to maintain focus over long times, you might consider using locktite to put it in place. More info here

McMaster 2

Z top:

Multi-Axis Measurement System MAX Scientific Instrument Co.

Illuminator:

SCIENTIFIC INSTRUMENT COMPANY SALES & SERVICE ... Date 12-00 Due 12-01

XY stage:

Nikon O2