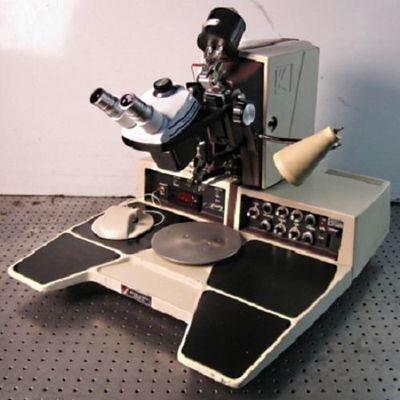

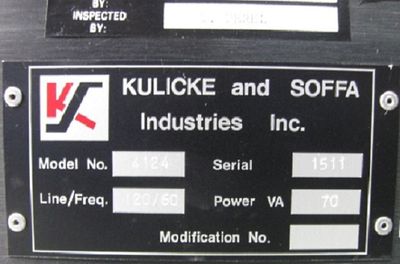

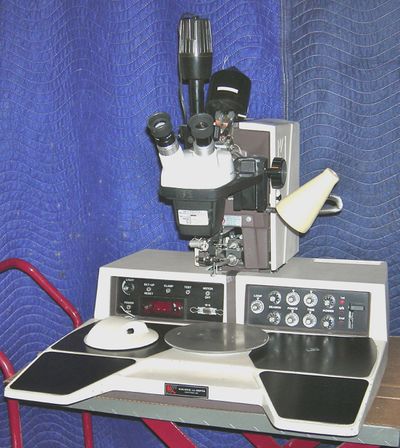

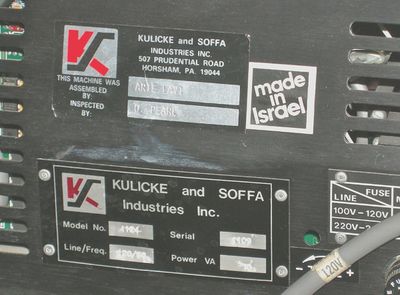

KS 4124

Specs

- Wire

- Gold 0.7 to 3.0 mils (17 to 75 um)

- Spool: TC-3 2" (50.8 mm) diameter, single flange

- EFO: 1200 VDC, adjustable

- Table

- Coarse: 6.5" diameter

- Throat depth (clearance head to table?): 5"

- Performance

- Temperature

- Controller: KTC-101

- Thermocopule: type J (iron-constantan)

- Operating range: 0 to 50C

- Set range: 0 to 400C

- Weight

- 64 lb w/o accessories

- 110 lb shipped w/o accessories

2018-03-08: mcmaster has two units on the way. One sourced locally at auction, one being shipped eBay freight. The eBay unit is pretty complete, although cosmetically isn't as nice. The local unit is reasonably complete, but may be missing a few simple bits like the wedge.

2018-03-15: both units have arrive. FabExchange unit unfortunately in much worse condition than I thought based on the pictures. For example, the inside electronics have been stripped out, and really the unit is just mostly taped together and missing a lot of screws. Its also missing drive belts and misc other covers. Fortunately the eBay unit, although has some missing paint and a little rust, is otherwise in pretty good condition. Preliminary tests indicate that it likely works

2018-03-25: contacted K&S, was told: "K&S no longer offers any manual wire bonder products and has ceased all related support services. You may want to contact Sharon Siso (...@mpptools.com) from MPP."

Contents

Calibration

4124 adjustments

Clamp solenoid

Section 6.1.5

Reccomended: 100g force at 5 mil gap

5 - 7 mil acceptable for 1-3 mil wire

Must be changed when loading different size wire

Use force gauge (scale?)

Adjust force with nut on right

Adjust distance with set screws on left

Bond force

Section 6.1.6

Use force gauge (scale)

Search height

Section 6.1.8

Set to 5 mil

Adjust search dial while chessman held down

EFO electrode adjustment

Section 6.1.11

Figure 3-8 on page 20 has items labeled

EFO vertical

1 mil wire => 30-30 mils below capillary

Greater gap => smaller wire

To adjust: loosen knurled knob

EFO horizontal

4 mm to left of capillary tip

Loosen solenoid clamping screw

SHCS allen key: 77 mil

EFO overtravel

50-60 mil beyond capillary tip

Loosen solenoid ring set screws

SS allen key: 34 mil

Capillary adjustment

SHCS allen key: ? couldn't get one to fit. Using pliers to tighten...

diameter: 1.47 mm

thread: 1.25 / 4 = 0.3125 mm

Capillary diameter: 1/16"

Allen key inserted for alignment: 56 mil

63 mil diagonol vs 1/16" => 63 mil

Wire loading

6.1.10

First o-ring 3/8" from flared side of funnel

150C workholder

Connectors

P14

Label: TEST

Suspect has serial port somewhere on it

| # | Color | Function | Note |

|---|---|---|---|

| 1 | 9.3.5 Set MOTOR switch ON and check for less than 6 Vdc DMM: -150 mV | ||

| 2 | DMM: 0.65V | ||

| 3 | DMM: -85mV | ||

| 4 | 9.27.5 in Manual Z does not function properly 6.1.18.5 in 6.1.18 Z-LVDT ADJUSTMENT +7.6 V Z up ("reset") –8.5 V Z down DMM: -230 mV | ||

| 5 | 9.3.4 With MOTOR switch OFF, rotate cam until LED 1 (RESET) lights up on logic board. Check for 7 Vdc DMM: 5V | ||

| 6 | 9.3.2 18 V ptp, 2.5 kHz sine wave DMM: -15V | ||

| 7 | DMM: 0V | ||

| 8 | DMM 15V |

PCB

The PCB in the schematic does not match my unit

Manual: parts table lists as 4124-4100-0 Logic Board Ass’y, image layout shows the same thing

Unit: 04125-4210-000-01

mcmaster eBay

Initial checkout

- Bonding cycle: okay. I hear it feeding wire, I see the clamp releasing, it goes though 1/2 (initial/finish) cycle, does a ball forming motion, etc

- Tried both the mouse and lever

- However, pulley band old / rigid and snapped after a little use. Need to replace

- Heated plate: heats

- EFO or w/e its called: flickering red power LED. I haven't tested EFO specifically, will have to see if its actually working once I get wire

- Targeting light: turns on, but I'm not seeing a reticle. Maybe needs some adjustment

- Goose neck illumination: seems to work

- TODO

- Order replacement pulley belt

- Order (gold) wire (size?)

- Investigate tip. Is it okay? Should I order spare/replacement?

- Order spare bulbs?

mcmaster FabExchange

Resolution: scrap for other unit. Too many missing parts / things wrong to consider repair

ebay outback6 291094800318

Source: eBay seller outback6

ebay amsi 352246425950_ks4124

Workholder

Controllers

- KTC-101-1: 115 VAC

- KTC-101-2: 230 VAC

Type J TC

| Pin | Function | Wire color | Notes |

|---|---|---|---|

| 1 | TC | Shrouded silver | +/-? |

| 2 | Ground? | Yellow w/ green | |

| 3 | Coil | Yellow | |

| 4 | N/A | N/A | |

| 5 | N/A | N/A | |

| 6 | TC | Shrouded silver | |

| 7 | Coil | Yellow | |

| 8 | N/A | N/A | |

| 9 | N/A | N/A |

Tried both TC polarities. One read 32, other 37C. Hmm

Coil resistance: 78.4 ohm. Around 1.5A

Couldn't get ground wire continuity on anything

Belt repair

Belt broke shortly after I started using it due to it being old and what not

Measured:

- 1/8" tube diameter

- 8.5" long => 2.8" OD

- polyurethane

McMaster doesn't sell OD below 4", so need to make one myself. I've ordered 1/8" material and will try to fit and join it. Suggestion is to fit it on the machine to length, then cut to allow for 10% stretching (ie cut 10% off).

Wire

References

- http://www.photonicmicrodevices.com/files/K_S_Ball_Bonder_4124_Spec.pdf

- Operation manual

- https://www.bu.edu/photonics/files/2016/11/4124-Data-Sheet.pdf

- Marketing blurb

- https://rsc.aux.eng.ufl.edu/_files/documents/144.pdf

- Excellent doc

- Similar unit page: http://lnf-wiki.eecs.umich.edu/wiki/Wire_Bonder

- 4123

- Guy referred to for professional bonder repair: George Garcia (http://www.pgent.net/about.html)

- Comes with excellent recommendation