Allied MultiPrep

Motor

Both motors (drive, osc) were identical

PITTMAN GM8712-41 19.1 VDC 187:1 RATIO MFG 05-29-98 S

33 and 17 ohm. Is one of these damaged? Why are their resistances so different?

Tried testing under load

- black goop

- 12.19 V @ 1.266 A (current limited)

- 8 ohm after

- other

- Initially drawing way less current than first

- 12.12 V @ 0.332 A (voltage limited)

- then started smoking

- 11.68 V @ 1.248 A (current limited)

- 6 ohm after

- Initially drawing way less current than first

Aren't these rated 19.1 V? Am I misunderstanding?

Try pinning out the spare bad head

- 1-5: 2.8 k

- 2-6: 147 R

- weird...

what does the secondary machine test? (believe good)

- 1-5: 9.0 R

- 2-6: 10.4 R

What is max voltage allied puts out on motors?

- 1-5

- 7.6 (fixed)

- osc

- 2-6

- 15.0 (max)

- drive

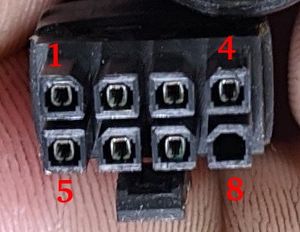

Head connector

Head plug

- 4x2 (8 pins)

- 3 mm pitch

- Head female, cable male

- Maybe Minitek Pwr™ 3.0 Series

- https://www.digikey.com/product-detail/en/amphenol-icc-fci/10132445-08LF/609-5283-ND/7590945

| Mini-amphenol | mini-DIN | Signal | Note |

|---|---|---|---|

| 1 | 1 | ||

| 2 | 2 | ||

| 3 | 8 | ||

| 4 | 7 | ||

| 5 | 3 | ||

| 6 | 5 | ||

| 7 | 6 | ||

| 8 | N/C |

| Mini-amphenol | mini-DIN | Signal | Note |

|---|---|---|---|

| 1 | |||

| 2 | |||

| 3 | |||

| 4 | |||

| 5 | |||

| 6 | |||

| 7 | |||

| 8 |

Motor on mini-DIN

- 1: drive motor +

- 3: drive motor -

- 7 V

| Mini-amphenol | cpc | Signal | Note |

|---|---|---|---|

| 1 | 8 | ||

| 2 | 6 | ||

| 3 | 1 | ||

| 4 | 4 | ||

| 5 | 5 | ||

| 6 | 3 | ||

| 7 | 2 | ||

| 8 | N/C |

Tach board

- Adapts 8 pin to 4 pin

- Includes cap + 4 pin SMD component (489, probably hall effect sensor)

- Must interface to those two red things I was confused about...looks like they have magnets on the end

- Minitek 4x2

- 1: 4x1.1

- 2: 4x1.3

- 3: hall, cap

- 4: hall

- 5: 4x1.2

- 6: 4x1.4

- 7: hall, cap

- 8: chassis ground

- 4x1

- 1: osc

- 2: osc

- 3: drive

- 4: drive

Test primary machine motor via 4x1

- drive: 10.2 R

- osc: 5.6 R

- *** out of spec

- consistent with a failed motor

failed motors appear to be caused by carbon buildup from brushes. They will fail very quickly if you operate them even close to their rated voltage. I was able to disassemble and blow one out to fix it. Now it runs at about 12.22V @ 350 mA. Current went down over time, maybe was 500 mA initially

Lets try another... initially 12.22V @ 1.25 A. Visible smoke. Rotor very dirty...should have cleaned other rotor. After cleaning dropped to 12.22V @ 1.1A and then rose up. Hmmm. Clean between rotar contacts. Success! Now 12.21 V @ 153 mA! Significant improvement! 9.6 ohm now

Back to original motor. Cleaned, now drawing 12.21 V @ 0.180 mA. Seems pretty concrete: needs to be cleaned, especially between rotar contacts. Try 18.86 V @ 197 mA. 9.6 ohm

Try osc motor. Didn't try running initially for fear of damaging. After cleaning (worst of all motors so far) 12.19V @ 175 mA. Current seems to be going down as well. 12.19 V @ 200 mA installed. However system is still not turning it (ie its not applying voltage). Other motor is about the same (even though it wasn't cleaned). Osc 9V on 8 pin. Osc motor being driven at 1.3V. Maybe power supply is failing? Current seems okay to me

McMaster

2020-01-14

- Win cross sectioning kit

2020-02-20

- Order sample holder

- Order replacement tubing

- Later found I had some spare, but meh can use for other projects

Primary

S/N 568

Hermitage: Allvia Sunnyvale? Not sure if they are still in business

2019-12-19

- Submitted offer. Negotiations failed

2020-02-19

- Seller accepted offer (was firm at old offer). Local pick up

2020-02-232

- Swap DRO from spare to primary machine

- Replace rusted micrometer

2020-02-23

- Observe osc motor is not moving

- Observe osc doesn't have slit like spare to keep in place...how is it supposed to work?

- Is this a DRM thing of sort where they didn't supply the right adapter if the user didn't purchase osc option?

- ie the motor was intentionally disabled and also mechanically hindered

Spare

???

- Won a few lots of parts TechPrep heads

- Goal: combine into one good head and mount on SBT machine

2019-03-20

- Try to get old TechPrep base. Negotiations failed

2019-12-20

- Won old TechPrep base machine. Change plan from retrofitting SBT machine to actually fitting on this machine

- Without reference machine a little difficult to piece together

- Machine filthy. Significant cleaning

2020-02-23

- Used reference machine to greatly accelerate repairs

- Made cable to hook up head

- E1.43 (error code?) persists, but machine seems to work fine